Caractéristiques

- Double joint

- Mtex-DN : Plan API 52 (53/54)

- Mtex9-DN : Plan API 53/54

- Cartouche

- Équilibré

- Indépendant du sens de rotation

- Soufflet métallique

- Ressorts fixes

- Dispositif de pompage indépendant du sens de rotation

Avantages

- Joint idéal pour la normalisation

- Application universelle pour les conversions de garnitures, les rétrofits ou les OEM

- Aucune modification dimensionnelle de la chambre d'étanchéité (pompes centrifuges) n'est nécessaire, faible hauteur d'installation radiale

- Fonctionnement sans problème grâce à l'unité à soufflet avec amortisseurs de vibrations (indispensable en cas de fonctionnement à sec)

- Pas d'endommagement de l'arbre par le joint torique soumis à une charge dynamique

- Effet autonettoyant du soufflet

- Installation simple et facile grâce à l'unité pré-assemblée

Plage de fonctionnement

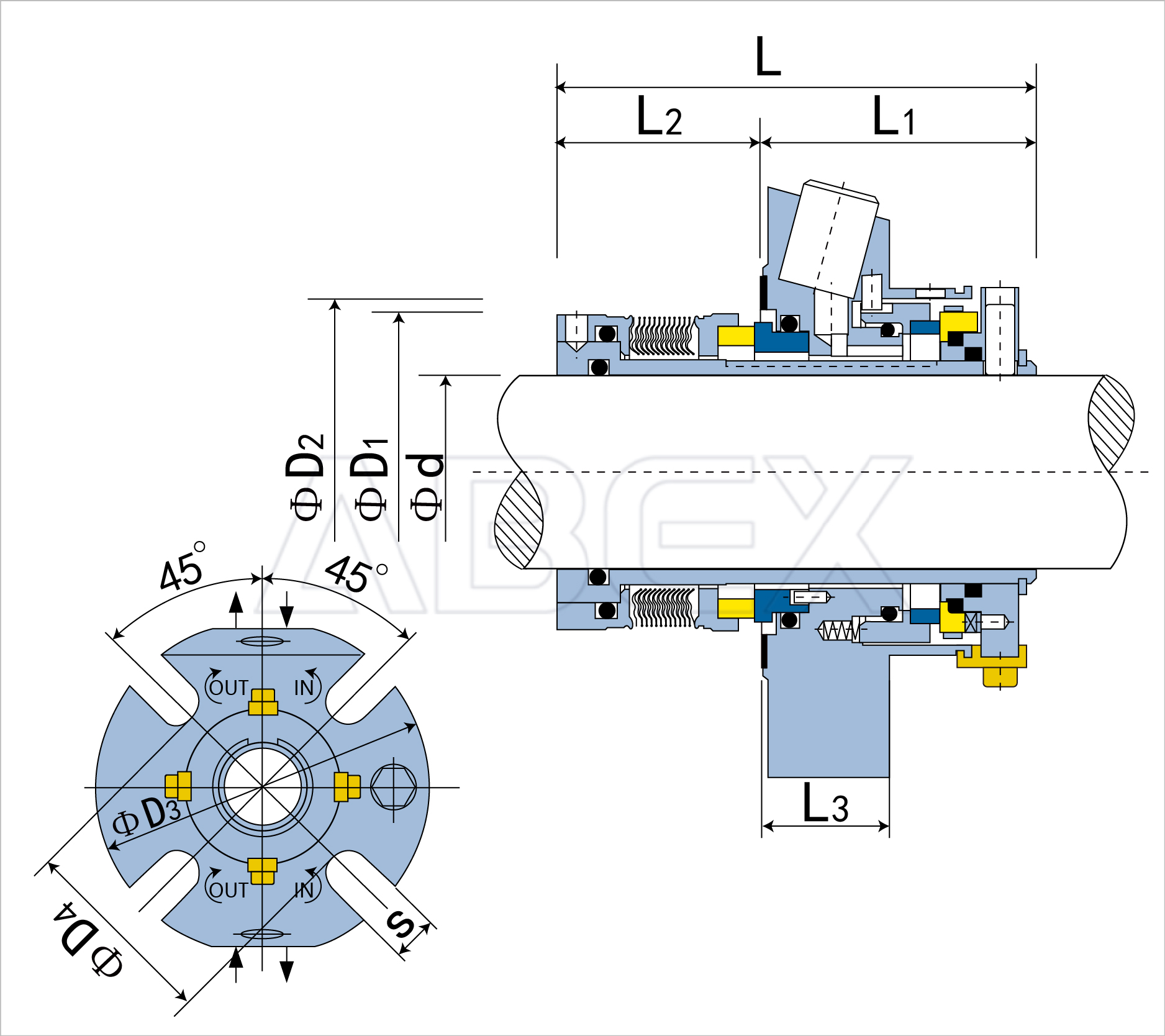

Diamètre de l'arbre :

d1 = 25 ... 80 mm (1″ ... 3.15″)

Température :

t* = -40 °C ... +220 °C (-40 °F ... + 428 °F)

Pression : p1 = 25 bar (232 PSI)

Vitesse de glissement : vg = 20 m/s (66 ft/s)

Système de circulation du fluide de la barrière :

p3max = 16 bar (232 PSI)

Δp (p3-p1) idéal = 2 ... 3 bar (29 ... 44 PSI)

Δp (p3-p1) max.

= 10 bar (145 PSI) à <120 °C (<248 °F)

= 5 bar (73 PSI) à ≤ 220 °C (≤232 °F)

Plan API 52 (53/54)

Démarrage de la pompe :

Δp (p3-p1) max.16 bar (232 PSI) autorisé

* Limites de fonctionnement des joints toriques à respecter

Matériaux

Face du joint :

Carbone graphite (A), carbure de silicium (Q1)

Siège :

Carbure de silicium (Q1), carbure de tungstène (U2)

Scellés secondaires :

FPM (V), EPDM (E), FFKM (K)

Soufflet : Inconel® 718 (M6)

Ressorts : Hastelloy® C-4 (M)

Pièces métalliques : Acier CrNiMo (G), Duplex (G1)