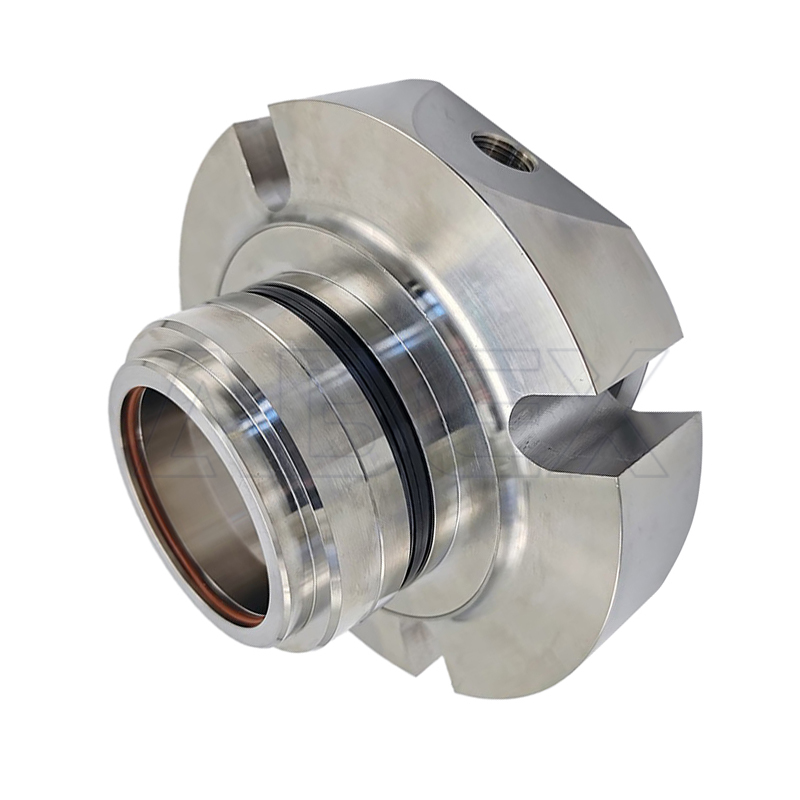

Se trata de un cierre mecánico de doble cartucho con doble equilibrado hidráulico adecuado para servicios con fluido auxiliar a presión o para fluido auxiliar a presión atmosférica (véanse los límites de funcionamiento). Ideal para aplicaciones pesadas con líquidos peligrosos, a altas temperaturas y presión. Fácil instalación gracias al nuevo dispositivo de posicionamiento Fluistrip y a las ranuras de las bridas que se adaptan a diferentes prensaestopas. El manguito reforzado tolera una mayor excentricidad del eje y se adapta a mezcladoras, secadoras, molinos y también al montaje directamente en el eje de la bomba.Se trata de una junta de cartucho equilibrada ”doble" que se autocentra en el eje, con muelles fuera del fluido. Adecuado para su uso en agitadores de entrada superior, lateral e inferior, y con fluidos en fase gaseosa, peligrosos, sucios o de alta viscosidad.

Esta junta de cartucho puede sustituir a la Fluiten CB3D.

Características

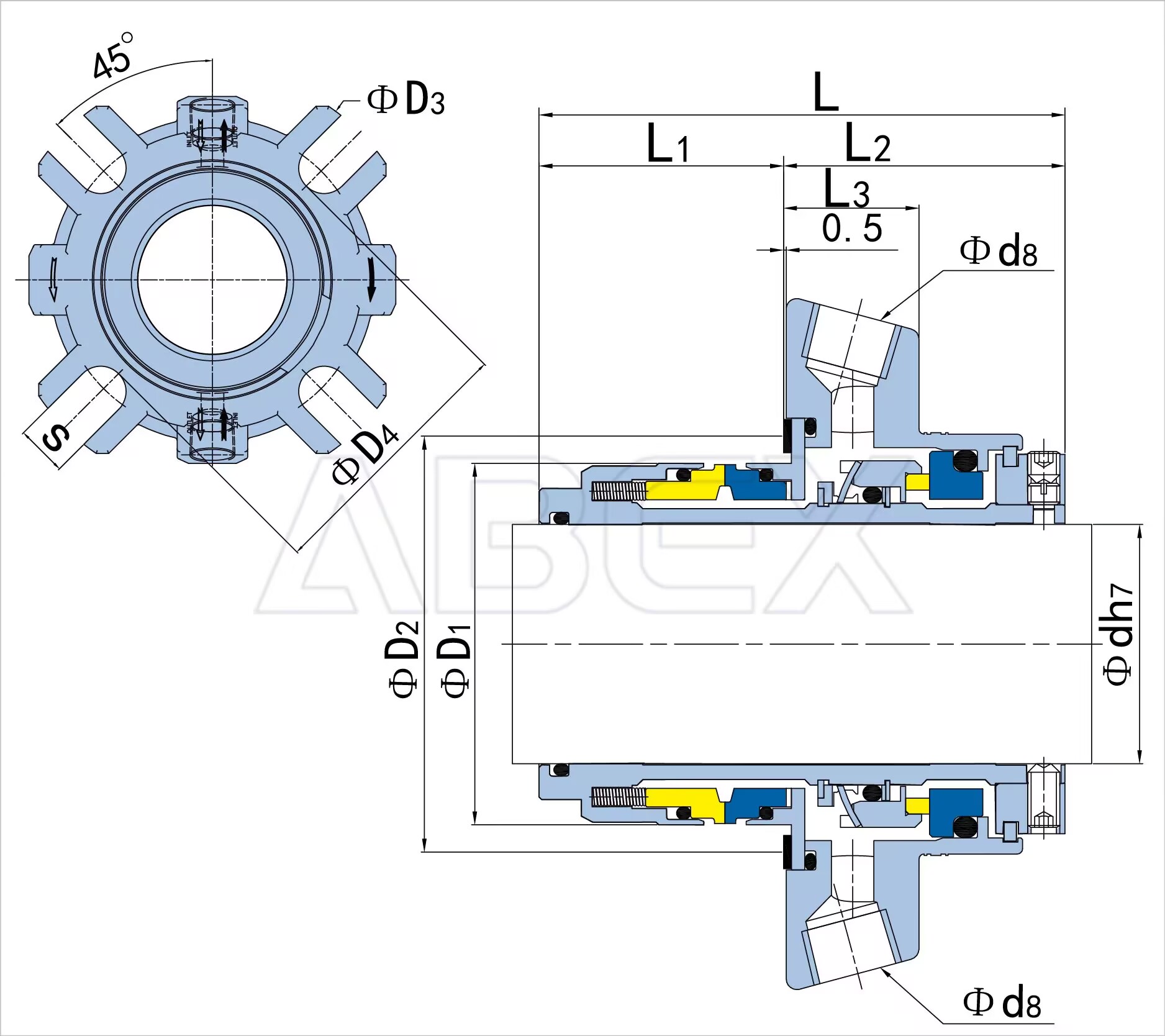

- Doble junta equilibrada para mejorar el rendimiento, capaz de tolerar inversiones de presión momentáneas.

- Conexiones de lavado para sistemas auxiliares (PLAN 52 o PLAN 53) o lavado desde una fuente externa (PLAN 54 o PLAN 55).

- Brida ranurada para un montaje más flexible.

- Fluistrip: dispositivo de posicionamiento para una instalación correcta y sencilla, que se extrae después del montaje pero antes de la puesta en marcha de la máquina.

- Junta auxiliar de grafito/carburo de silicio con líquido de lavado fuera de las superficies de la junta para evitar el sobrecalentamiento.

- Dispositivo de bombeo bidireccional para líquido de lavado.

- Dispositivo patentado de accionamiento por anillo giratorio en el lado atmosférico con dimensiones axiales reducidas.

- Manguito más grueso para tolerar valores de excentricidad elevados y evitar deformaciones durante el mantenimiento y el montaje.

- El dispositivo de accionamiento deslizante compensa cualquier movimiento y mantiene el contacto con el anillo giratorio.

- Muelles fuera del producto y perfil limpio para una mayor fiabilidad incluso con productos viscosos que cristalizan, y también en procesos que requieren una limpieza a fondo