Features

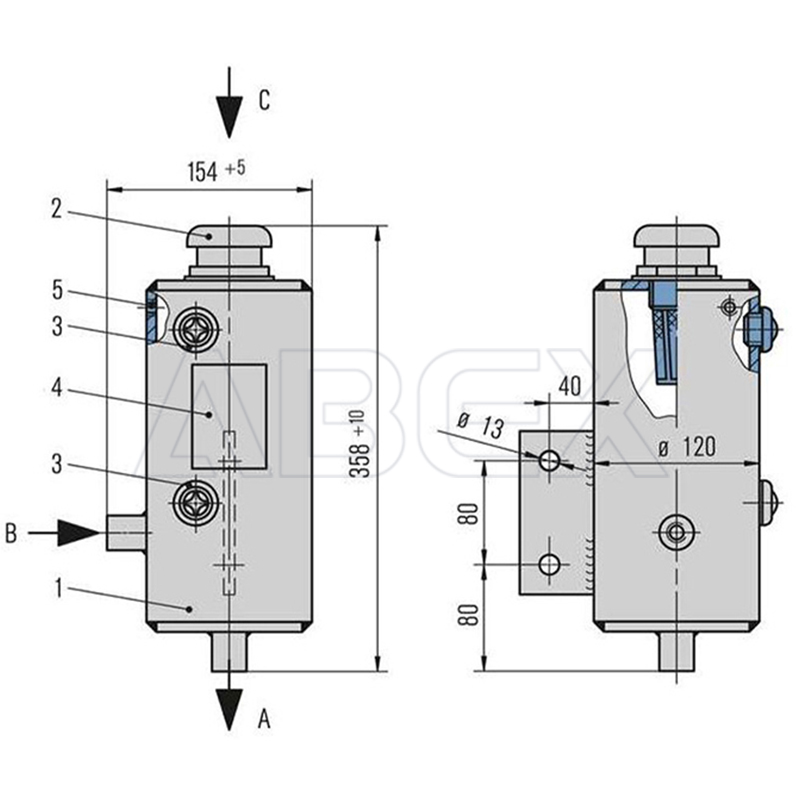

Quench fluid supply systems are used to supply single or tandem mechanical seals. They act as a convenient fluid reservoir. The exchange of fluid takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw. The QFT2000 stainless steel tank is equipped with sight-glasses for monitoring the MIN/MAX level and can be fastened with a lug fixture. The leakage overflow can be selectively discharged.

Supply of mechanical seal based on API 682 / ISO 21049, Plan 51.

Advantages

- Available in a range of different material combinations: suitable for a wide range of demanding operating conditions

- Design for medium temperatures of up to +200 °C (+392 °F)

- Tank made of 1.4571: high resistance to corrosive media

- Integrated overflow for selective discharge of leakage

- Instead of the sight-glass it is possible to use a level switch to monitor the fluid volume

- Combined filling and ventilation filter in the quench fluid tank for reliable operation

Recommended applications

- Chemical industry

- Food and beverage industry

- Pharmaceutical industry

Functional description

Quench fluid systems are employed:

- to absorb leakage

- to monitor the leakage rate (e.g. through periodic reading of the level in the tank)

- to lubricate and to cool the outboard mechanical seal in a tandem arrangement

- to prevent icing

- to protect against dry running

- to stabilize the lubricating film

- to exclude air from the media in order to prevent a reaction with oxygen in the air