Features

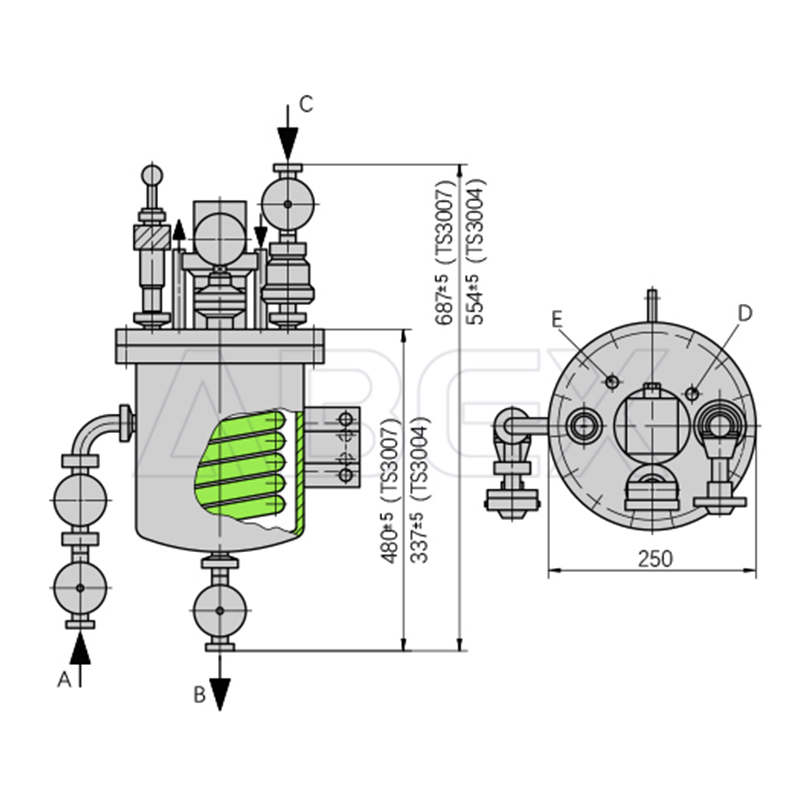

Thermosiphon systems of the TS3000 range designed specifically for the operation and supply of mechanical seals in sterile processes. The TS3000 thermosiphon vessel is available in two standard sizes, designed for dismantling, with cooling coil. The modular system allows the TS3000 vessels to be combined with a wide range of system components.

Circulation based on API 682 / ISO 21 049: Plan 52, Plan 53A.

Advantages

- Can be fully sterilized: TS3000 thermosiphon system, including all components and pipe couplings

- Surfaces are electropolished on all sides: effective cleaning and reduction of bacteria growth

- Vessel can be dismantled: the joint is sealed at the inner diameter by an O-ring without any gaps

- FDA-conform materials, therefore suitable for hygienic applications

Standards and approvals

- PED 2014/68/EU (Design and production in accordance with EU Pressure Equipment Directive)

- Compliant to TA Luft (German Clean Air Act)

Recommended applications

- Food and beverage industry

- Pharmaceutical industry

Functional description

The TS system performs all the basic functions of a buffer/barrier system for the operation of double seals:

- to pressurize the buffer chamber

- leakage compensation

- buffer/barrier fluid is circulated by thermosiphon effects

- to cool the seal

- to selectively absorb product leakage and prevent dry running (tandem arrangement)

In addition to performing the basic functions of a buffer system, the TS3000 system can also be used to make condensate, provided the TS system is connected up to a steam pipe