Features

- Successor of product lines TS2000, TS1020

- For ANSI pumps in chemical applications

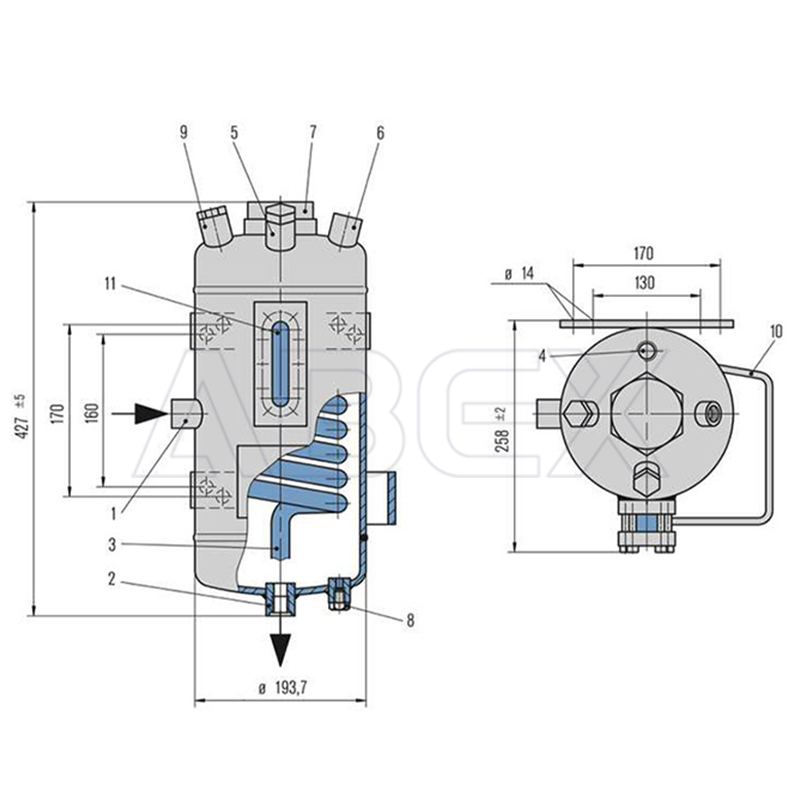

- Pressure rating up to 25 bar(g) (362 psi)

- 40 % increased working volume compared to previous version

- Sight glass for level monitoring

- Cooling coil is supplied as standard

- All necessary system connections and brackets are provided as standard for optional components

- Circulation based on API 682 / ISO 21 049: Plan 52, Plan 53A.

Advantages

- Improved heat dissipation

- Material of construction 316/316L – 1.4401/1.4404 stainless steel; sight glass made of borosilicate glass

- Modular system design, many pre-configured variants available

- Sleeves with recessed gasket prevent contamination of circuit by thread sealant

- Very short delivery time

- Attractive pricing

Standards and approvals

- ASME VIII, Div. 1 (Design, calculation and production)

- PED 2014/68/EU (optional)

- SELO, TR CU on request

- Compliant to TA Luft (German Clean Air Act)

Recommended applications

- Chemical industry

- Petrochemical industry

- Oil and gas industry

- Refining technology

Functional description

The TS system performs all the basic functions of a buffer/barrier system for dual seal operation:

- Pressure-build-up in the seal chamber

- Leakage compensation

- Circulation of the buffer/barrier fluid by thermosiphon effect or forced circulation

- Cooling of the seal

- Selective absorption of product leakage and prevention of dry running (tandem arrangement). When pressurized, this is provided via compressed air or nitrogen.