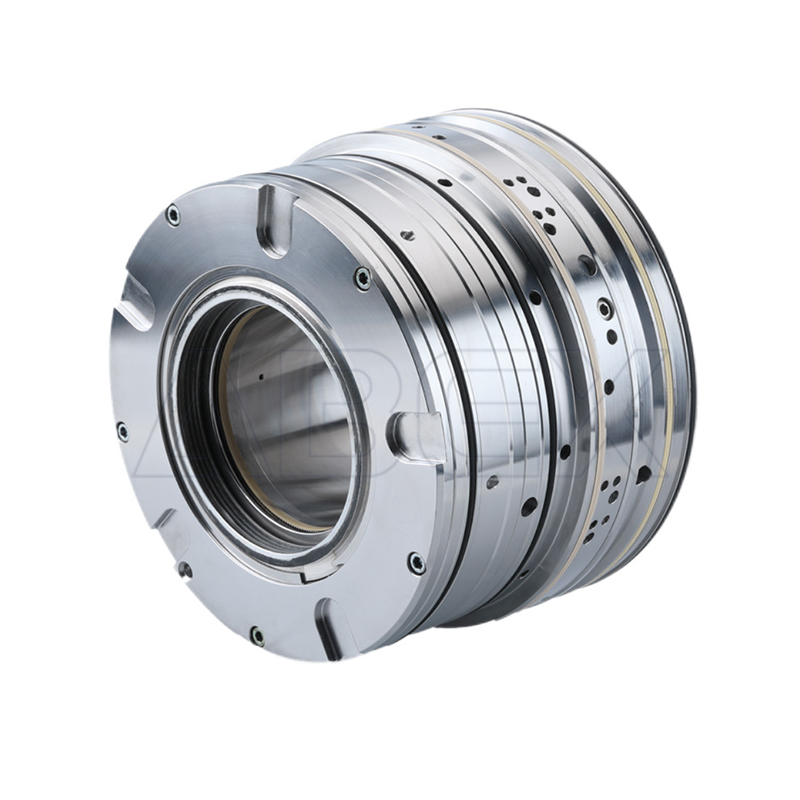

Features

The sealing solution for reduction of methane-/ process gas emissions

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

- Available for following seal arrangements: single and tandem

- Co-axial primary seal

- Separation seals as CobaSeal, carbon rings or labyrinths optional

Advantages

- No methane-/ process gas emissions

- Supplied with clean nitrogen (no dew point and dirt problems)

- Robust

- Offers higher safety than a double seal

- Upgrade-possibility of existing single, double and tandem seals

- No modification of the compressor necessary

- Efficient alternative to hermetically sealed systems

- For compressors with gas- and steam turbines, as well as with electric drive

CobaDGS eliminates methane emissions.

The CobaDGS reliably prevents any process gas emissions that are technically caused by primary seal leakage during compressor operation. This makes CobaDGS the most climate-friendly sealing solution for high-pressure turbo-compressors. It is recommended as a sustainable sealing solution for modernization of existing compressors and as a first fit for OEM.

Operating range

Shaft diameter:

d = 24.5 … 360 mm (0.96“… 14.17“)

Pressure (static and dynamic):

p = from vacuum up to 160 bar (2,321 PSI)

Design temperature:

t = -46 °C … +230 °C

(-51 °F … +446 °F)

Sliding velocitiy:

vg = up to 140 m/s (459 ft/s)

Project specific special designs possible.

Materials

Stationary seal face: Silicon carbide with DLC-coating, DiamondFace-coating optional

Rotating seal face (Seat): Silicon carbide with DLC-coating, DiamondFace-coating optional

Secondary seals: FKM or other elastomers, depending on product gas composition

Metal parts: 1.4006 or other stainless steels

Other materials on request.

Dimensions on request.