Features

- For top entry drive;

side drive also available on request - For stainless steel vessels

- Dry-running

- Modular and flexible design

- Compensation of shaft deflection by patented technology

- Independent of direction of rotation

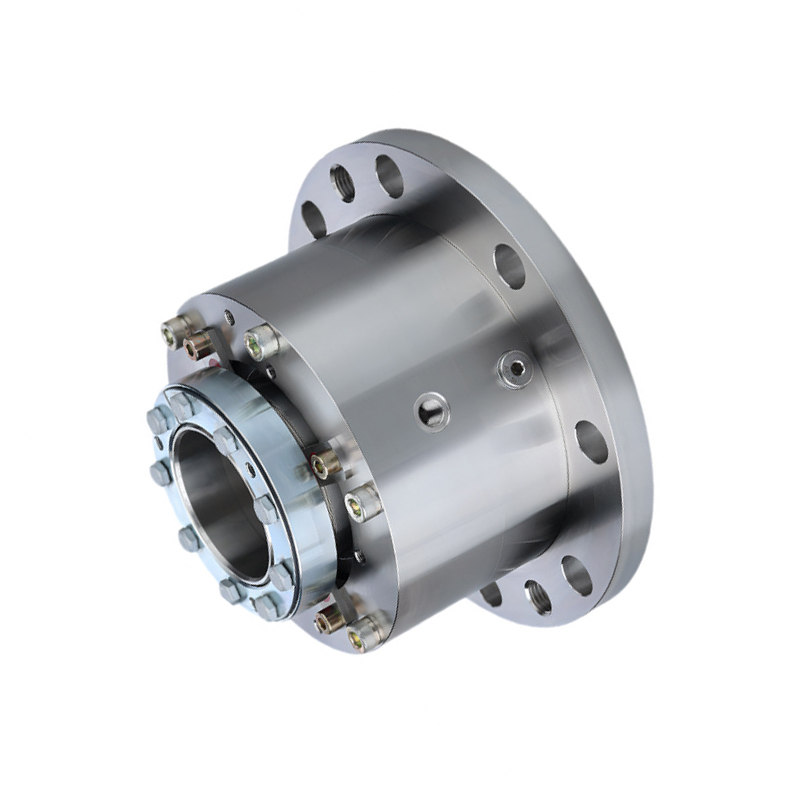

- Cartridge unit

- Variant available for applications with product contact (SeccoLipR)

Advantages

- Available as a ready-to-install cartridge for quick and easy installation

- Tested technology ensures safe use

- Dry-running lip seal – depending on the application no supply system is necessary

- No additional rolling bearing required, but optionally available

- Sealing element made of bright chemically highly resistant PTFE compound

- ATEX type examination certificate available

- CIP/SIP-compatible

- Flush possible

- Available with 2, 3, or 4 sealing lips

- No temperature monitoring required

- Further customer-specific adaptations possible

Operating range

Shaft diameter (on stock): d1 = 40 … 125 mm (1.57″ … 4.92″)

Special shaft diameters between 25 mm and 200 mm possible (0.98″ … 7.87″)

Pressure: p1 = vacuum … 6 bar (87 PSI)

Temperature: -30 °C … +200 °C (-22 °F … +392 °F)

Sliding velocity: vg = 0 … 2 m/s (0 … 6 ft/s)

Axial movement: ±3.0 mm

Radial movement: 1.0 mm (up to 3 mm on request)

For applications beyond this range, please inquire.

! It should be noted that the extremal values of each operating parameter cannot be applied at the same time because of their interaction.

Materials

Lip sealing element: bright chemically highly resistant PTFE-compound (FDA-compliant)

Secondary seals: FKM (V)

Metallic parts: 316L / 1.4404