Features

- Single seal

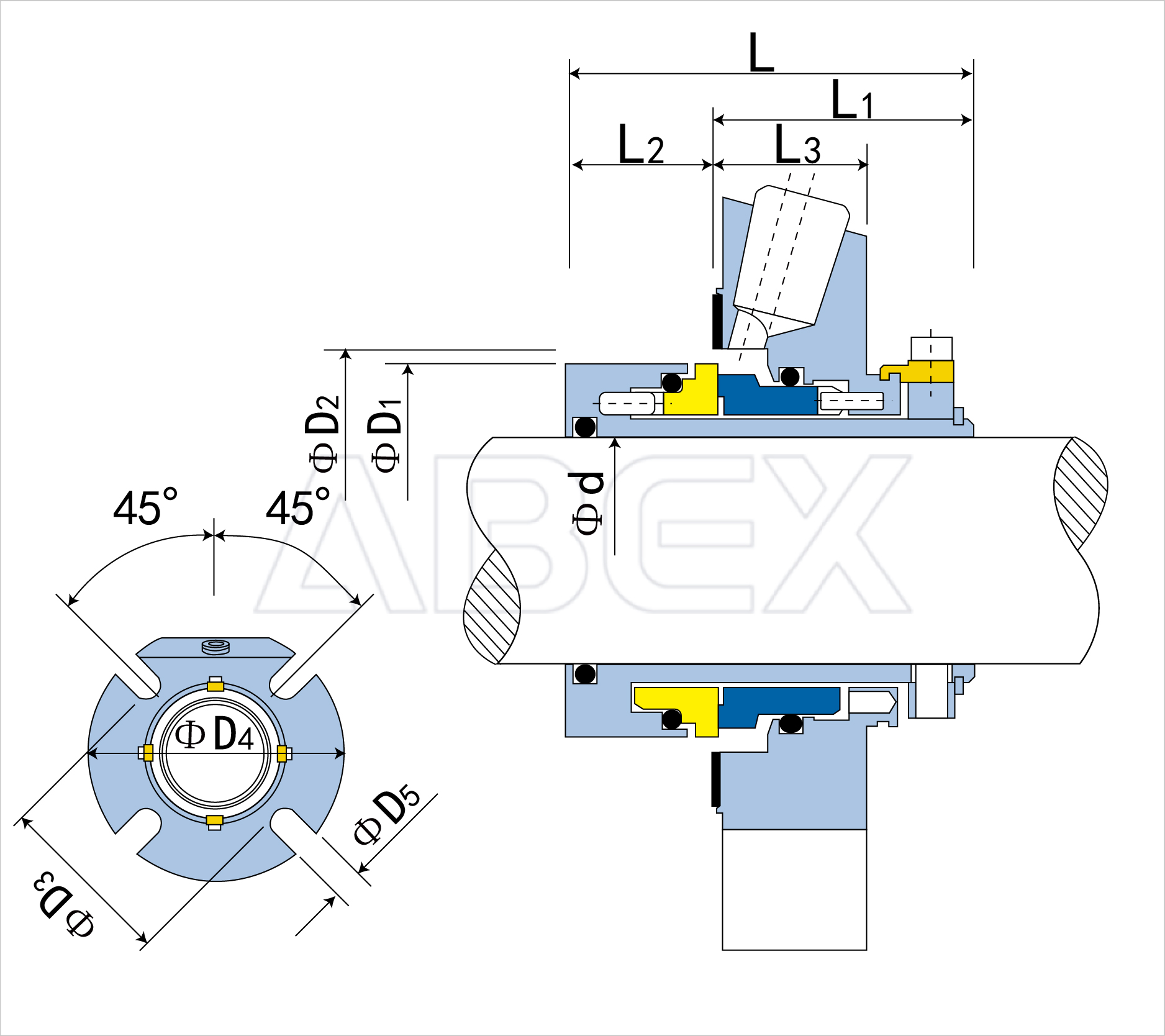

- Cartridge

- Balanced

- Independent of direction of rotation

- Single seals without connections (-SNO), with flush (-SN) and with quench combined with lip seal (-QN) or throttle ring (-TN)

- Additional variants available for ANSI pumps (e.g. -ABPN) and eccentric screw pumps (-Vario)

Advantages

- Ideal seal for standardizations

- Universal applicable for packings conversions, retrofits or original equipment

- No dimensional modification of the seal chamber (centrifugal pumps) necessary, small radial installation height

- No damage of the shaft by dynamically loaded O-Ring

- Extended service life

- Straightforward and easy installation due to pre-assembled unit

- Individual adaptation to pump design possible

- Customer specific versions available

Operating range

Cartex-SN, -SNO, -QN, -TN, -Vario

Shaft diameter:

d1 = 25 … 100 mm (1.000″ … 4.000″)

Other sizes on request

Temperature:

t = -40 °C … 220 °C (-40 °F … 428 °F)

(Check O-Ring resistance)

Sliding face material combination BQ1

Pressure: p1 = 25 bar (363 PSI)

Sliding velocity: vg = 16 m/s (52 ft/s)

Sliding face material combination

Q1Q1 or U2Q1

Pressure: p1 = 12 bar (174 PSI)

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement:

±1.0 mm, d1 ≥75 mm ±1.5 mm

Materials

Seal face: Silicon carbide (Q1), Carbon graphite resin impregnated (B), Tungsten carbide (U2)

Seat: Silicon carbide (Q1)

Secondary seals: FKM (V), EPDM (E), FFKM (K), Perflourocarbon rubber/PTFE (U1)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), CrNiMo cast steel (G)