Features

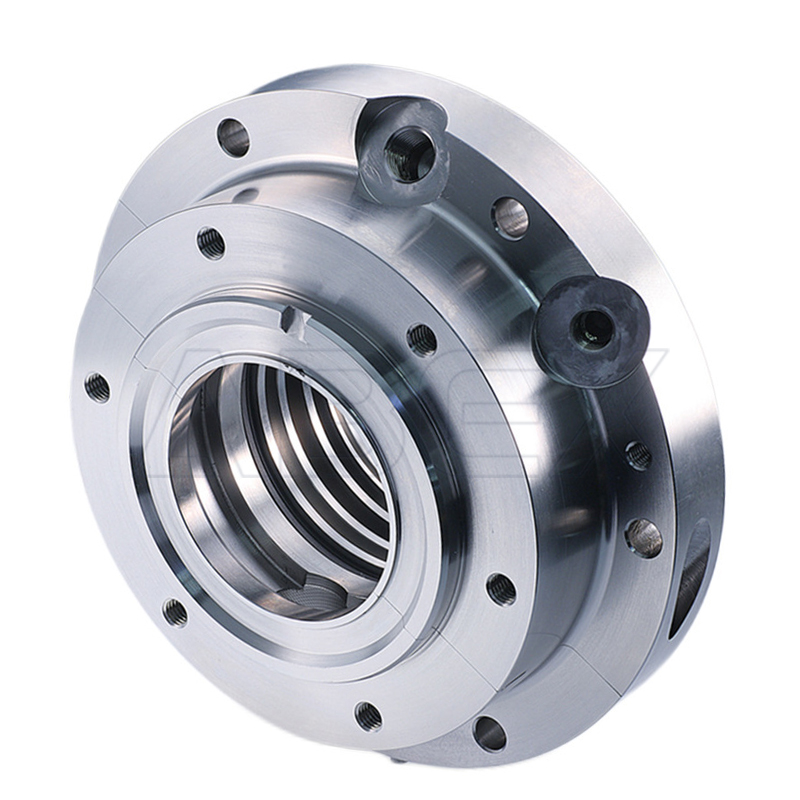

- Multi-part seal rings, radially cut on process side, overlapped mortised with gas tight joints on atmosphere side (adjusting)

- Split housing design

- Lowest possible operation gap – lowest leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- Short axial installation length

- No sealing components mounted on the shaft and hence no additional shaft vibrations

Advantages

- Easy installation by split housing design (shaft removal not required)

- Long-term operation time

- Maintainability

- Segmented seal rings for easy replacement

Operating range

Shaft diameter:

d = 45 … 340 mm (1.77″ … 13.89″)

Operating pressure: p = vacuum … 3 bar (44 PSI) abs. (depends on peripheral velocity)

Operating temperature: t = -120 °C … +500 °C (-184 °F … +932 °F) for carbon,

-120 °C … +150 °C (-184 °F … +302 °F) for PTFE compound

Sliding velocity:

vg = max. 40 m/s (131 ft/s)

Radial play: ±2.5 … 5.0 mm (±0.1″ … 0.2″)

Axial movement: theoretically unlimited

Recommended wear guard: >58 HRC

Materials

Seal ring: Carbon, PTFE compound

Housing: 1.4021, 1.4571, Hastelloy®, Titanium, Inconel®, others

Tension spring / detent: 1.4571, Hastelloy®, Titanium, Inconel®