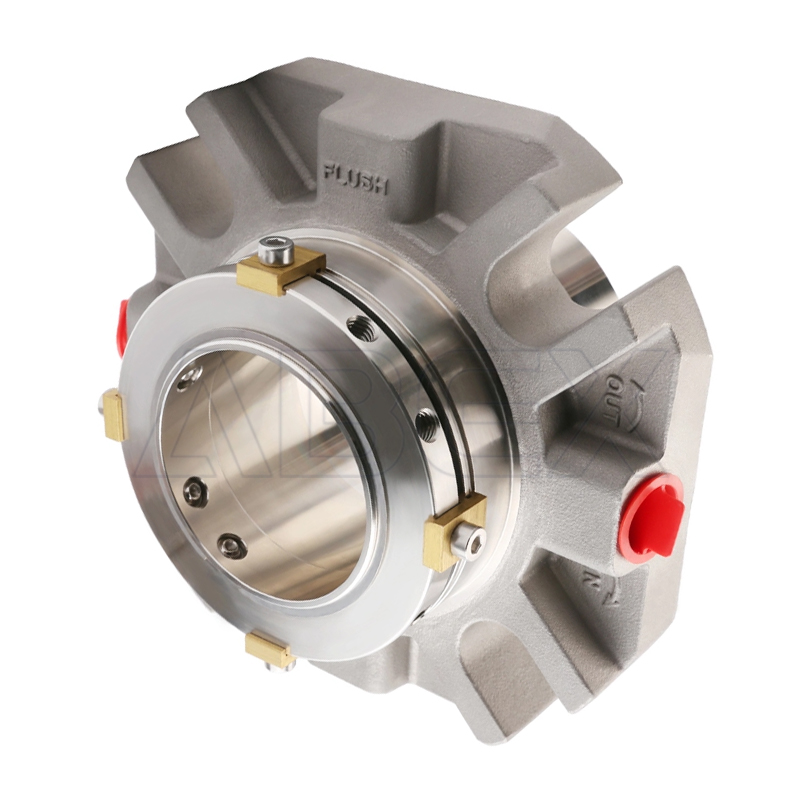

Double Mechanical Seal

The CDFI™ / CDFC™ bridges the product range gap between the FIDC™ and DMSF™ differentiating itself in two areas. The hybrid design offers a metal-to-metal inboard drive and an integral bi-directional pumping device, allowing the seal to fit in radial cross sectional spaces as small as 0.312″ (8mm). The CDFI™ / CDFC™ is available in any AESSEAL® standard seal face and elastomer combination.

Features:

- Integral deflector guides barrier fluid under faces and extends seal life

- Incorporates highly effective bi-directional pumping ring to maximise barrier flow and increase seal life

- Bi-Metal CDFI™ / CDFC™ options also include exotic allow wetted components at minimum price premium for use with corrosive chemicals

- Hydraulically balanced seal-face technology for reduced power consumption

- Non-shaft-fretting sleeve elastomer and positive set screw shaft drive

- Independent seal face design to enhance safe containment of process fluid in the event of damage to any individual sealing element

- Multiple spring seal face loading

- Sizes available from 1.125″” to 5.000″” (28mm – 125mm) in standard and ANSI Plus gland formats

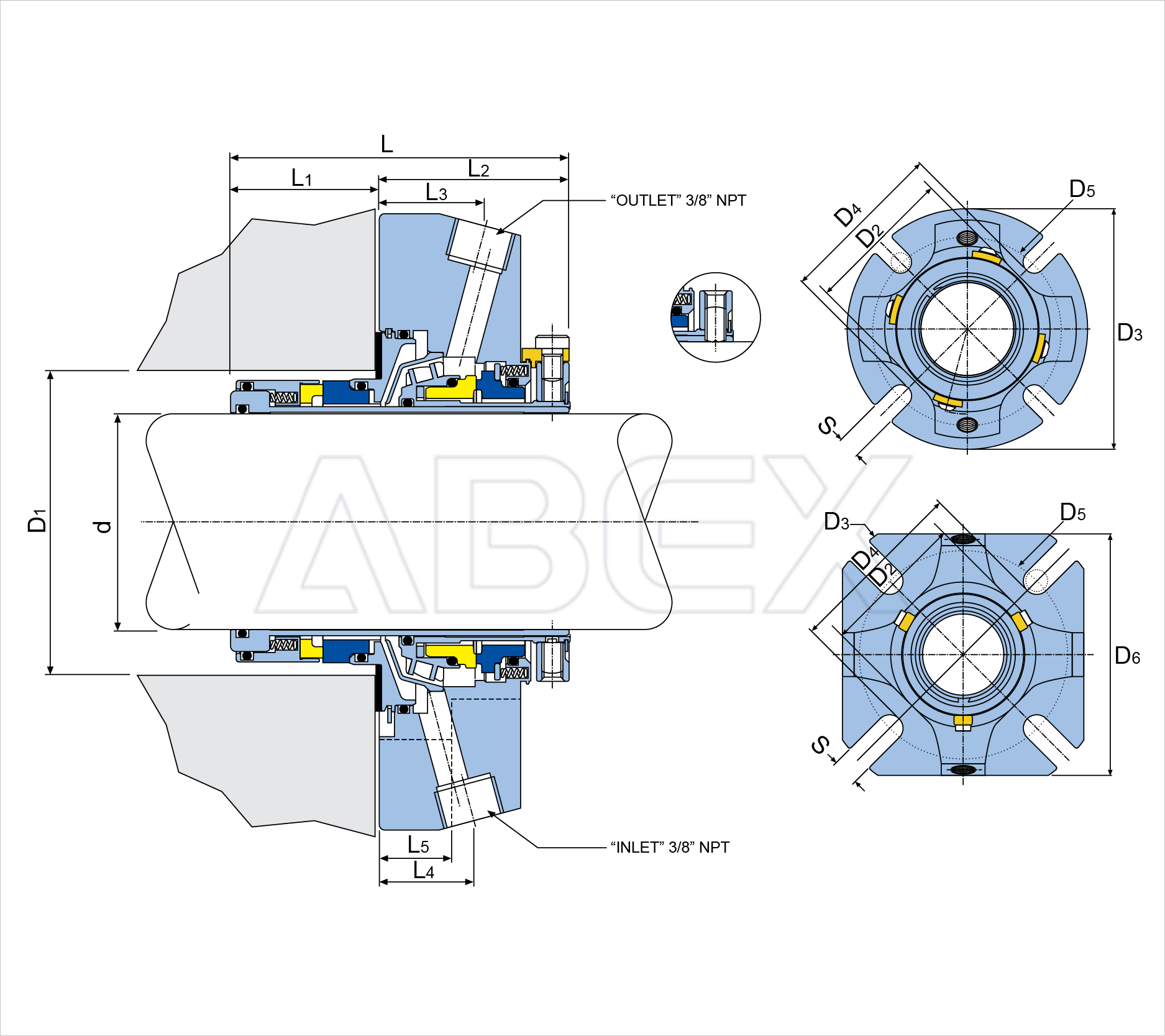

Directed Barrier Fluid Circulation

Removing the heat at the inboard faces is critical for any double mechanical seal. The CDFI™ / CDFC™ directed barrier fluid flow path achieves effective heat removal at both sets of seal faces.

Bi-directional Barrier Fluid Circulation

Developed using the highly efficient patented DMSF™ pumping ring the CDFI™ will effectively and reliably circulate barrier fluid irrespective of the direction of shaft rotation.

Alternatively, in applications which use an external barrier fluid circulation device, such as a PUMPPAC™, or where fluid convection is required, the CDFC™ may be offered.

Fits in Thin Radial Cross Sectional Spaces

Like the FIDC™, the CDFI™ / CDFC™ can be installed on equipment with radial cross sectional spaces as small as 0.312” (8mm). This is typical on some smaller sized process pumps.