CDP™/CDPN™ range of cartridge mechanical seals has been designed as high-performance sealing solutions for general applications.

These products build on over a decade of proven performance from the AESSEAL® CURC™ and FIDC™ range of seals. They combine this with cutting-edge manufacturing techniques to represent the best value-for-money sealing solutions available today.

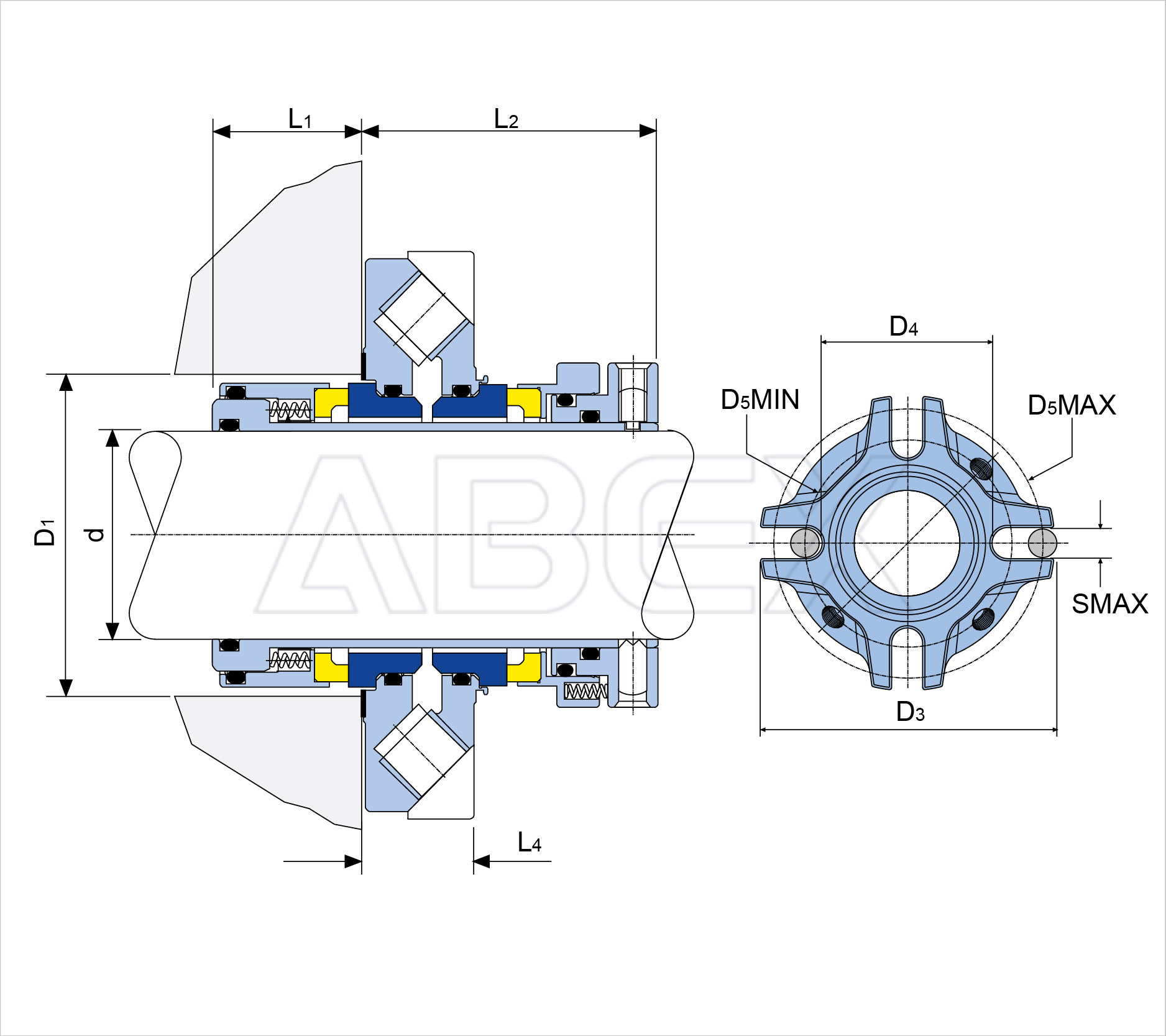

Features:

- Modular range of cartridge double mechanical seals for general applications

- Supplied with Quench, Flush and Drain ports as standard

- Hydraulically balanced seal-face technology for reduced power consumption

- Non-shaft-fretting sleeve elastomer and positive set screw shaft drive

- Independant seal face design to enhance safe containment of process fluid in the event of damage to any individual sealing element

- Multiple spring seal face loading

- Sizes Available from 1.000″ to 3.500″ (24mm – 85mm) in standard and ANSI plus gland formats. Larges sizes termed CDP™